What's Needed,Safety,Customer Service

What's Needed,Safety,Customer ServiceTHE NATION’S TOP TYPE A BUS

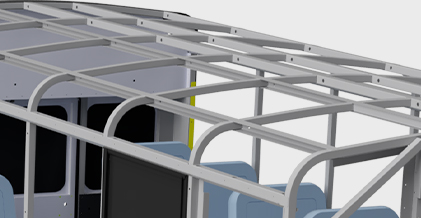

INTERLOCKING CROSS MEMBERS

Our full-Length, interlocking longitudinal cross members and floor beams are an essential component to student protection. The interlocking design creates a roll cage structure that offers better rollover protection, side impact protection, and a bus that is 5X stronger.

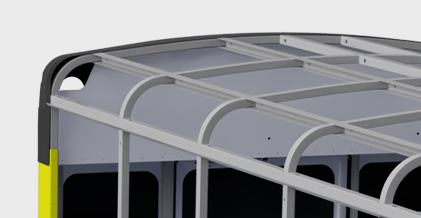

ONE-PIECE TUBULAR ROOF BOWS

Like the hull of a ship flipped on its head, the one-piece tubular roof bows form a sturdy shell that prevents crumpling or breakaway if there’s a rollover. Plus, Collins roof bows are made of high-strength low-alloy (HSLA) steel, which is 66% stronger than the steel commonly used.

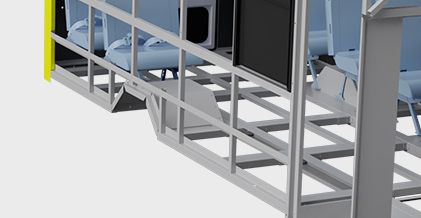

INTERLOCKING FLOOR BEAMS

Every Collins school bus utilizes interlocking floor beams that hook to one another to create a cage that delivers extra strength. Plus, because our flooring is made of one-piece marine grade plywood and not separate panels, it would require significant force to break or splinter under duress.

“We put all the Type A buses side-by-side, then let our drivers and mechanics get in and poke around. Both liked Collins better. Our mechanics liked the serviceability, and everyone liked the driver’s compartment and overall look.”

– Pam McDonald, Director of Transportation for Orange Unified School District“Small chassis buses, that’s what you build. And you’re good at it – you’ve perfected it.”

– Mia Sedillo, Director of Transportation for Chino Valley Unified School District

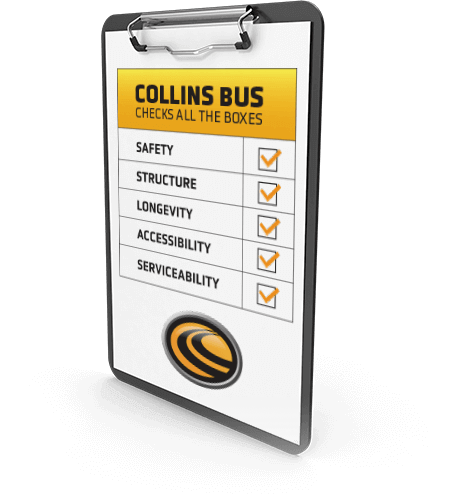

Placed side-by-side with a competitor’s bus and asked which one drivers and mechanics prefer, Collins didn’t just get best style or function or best serviceability; it got all of them. Now, we could talk comparisons all day. We could go on and on about how we raise the bar on bus safety, structure, longevity, and accessibility. We could, but we’d rather you heard it from current Collins customers.

So, ask yourself, are you getting the

most out of your school buses?

At Collins, every employee, from our CEO to our trusted Dealers, is front and center when it comes to customer needs. That’s because we believe personal relationships make all the difference. For owners and their passengers, that translates to long-term solutions, faster response times, expert advice, and trusted transportation from the wheels to the roof.

When it comes to customer service,

We build high-quality relationships.

WE BUILD BUSES 5X STRONGER

In addition to passing the most rigorous of industry safety tests, at Collins, we put our buses through the ringer to ensure they don’t just pass, but rather set a new bar in school bus safety. And, we don’t stop there. We also put our buses through internal tests (like the video here) to ensure student safety is addressed from every angle.

LET’S MAKE SURE YOUR STUDENTS

GET THE PROTECTION THEY DESERVE

At Collins, our number one priority is student safety to and from school. And that starts with a strong, reliable bus and a team never willing to settle for second-best protection. It’s why we hope school districts everywhere will look to Collins for their fleet needs, now and in the future.